By: Jill Thiede, Leader of Smart and Connected Services

In a recent regional survey in the Midwest, mid-to-large size manufacturers were asked about their plans for Industry 4.0. While 35% of the responding companies reported having “no plans”, and 55% had “some plans”, it was the response from the approximately 10% that had a “complete plan” to deal with Industry 4.0 that really shocked me. In the past year that I have actively engaged with Industry 4.0 concepts, ideas, and approaches, the key thing that I learned is that Industry 4.0 is a continuous journey – not a destination.

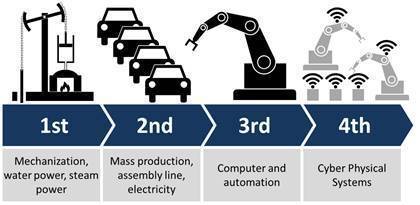

Industry 4.0 can mean a lot of different things to a lot of different people. And some marketing campaigns have tried to obscure the definition with smoke, mirrors and especially clouds. Industry 4.0 is referring to the merger of automation and big data in manufacturing – including the implementation of IIOT (industrial Internet of Things), cyber-physical systems, machine learning, and ultimately artificial intelligence.

As companies are assessing their current capabilities and determining how to approach this daunting subject - start small, learn quickly, fail fast, then rinse and repeat. There are so many areas that have promise and potential. Technologies are emerging so rapidly, that you cannot wait to have a “complete plan” to address ALL of Industry 4.0 before you start. Rather than being paralyzed by the overwhelming nature of this Fourth Industrial Revolution, pick an area that has potentially largest impact on your company, and start learning. Then start a test case. Engage your key thought leaders. Create energy with each new learning and success. Failures are a part of the process, but try to fail as soon as possible, and move on. Test and Learn. This is the mantra that should guide your journey.

As you evaluate the various opportunities, determine when to develop an “in-house” solution, when to partner with an expert for a semi-custom approach, and when to purchase “off-the-shelf”. The time scale for new technologies has shifted. What used to take 3-4 years, is being done in 12 months. It is critical to take any advantage possible through partnerships and suppliers.

Taking the first step is the hardest. But, it is necessary. It is estimated that 40% of the companies currently in the Fortune 500 companies will not be in business ten years from now according to a study by the John M Olin Schools of Business at Washington University. The key is understanding how “big data” can really help make your company money. Begin by focusing on a problem that using data can solve. Focus on the solution to that problem, and not just the technology. The data needs to drive insights that can drive real actions that affect productivity, or reliability, or more cases out the door.

Start small, but start! Test and Learn.