As first seen in Labels and Narrow Web magazine - April 2018

MEASURING COAT WEIGHT

In my travel from place to place there are many customers that do not measure their coat weight (CW). They may maintain their coatings by gloss or scuff resistance, which is at least a benchmark to set but there are also many that do not measure their CW readings at all and just use visual acceptance. This is like driving a car without a gas gauge. You need to know in real time how much CW is being applied.

Creating a coat weight paramewter is the best way to set an acceptable range for any coating application. Substrate variations can change the final CW on an application. Different batches or suppliers of any substrate could cause a variation in CW. Start by designating an area to set up the proper instruments needed for measuring CW. This is the best way to ensure that all coatings will meet the requirements of the product demand. Measuring CW will also ensure that the CW parameter needed is being maintained and you know the pass or fail limitation.

THERE ARE TWO TYPES OF COATING METHODS WHERE ANILOX ROLLERS ARE CONCERNED

• Flexographic process uses a typical transfer roller or polymer plate.

• Gravure can have a number of methods such as reverse gravure, variable speed, offset gravure and standard gravure with a 1:1 roller to web speed. All methods deposit the coatings differently. Ceramic anilox rollers need to be finished in a different manner if being used in the direct gravure method to the substrate, especially when using lower linescreen engravings. Chrome rollers were the standard for many years, and they have a much lower surface tensionand allow for the slip needed in the variable speed gravure applications. You have to achieve a similar finish in ceramic to get the same result.

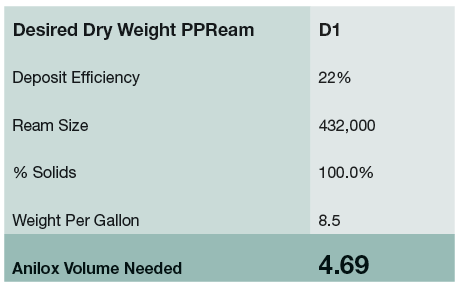

The example shown here is utilizing a standard coat weight calculator. You can use one to calculate the CW based on the parameters listed. The deposit efficiency can vary based on how your anilox is transferring the inks or coatings and the total design of your transfer process. We use 22% for flexo and 40% for gravure as a starting point.Once you get more familiar with making these recommendations, you will get much better with determining the actual efficiency rating. Measuring the current output is essential to understanding transfer efficiency. Line screen and volume of the anilox, as well as the coating chamber on the press and any other variables that are related to the fluidity of the coating, can affect the deposit efficiency. Viscosity,durometer of transfer roller or polymer plate, backer roller if gravure,may also skew the final CW.

OPTIMIZING THE CW

Coat weight needs to be regulated for a number of reasons. Prouct protection is one. Product features may require scuff resistance, detergent resistance, water, steam, ink bleed, etc. This list can go on depending on the product that is being coated. The amount of CW being applied will make a difference on how well the label, flexible bag or folding carton will hold up to the environment it will be exposed to everyday.

Every substrate should be well tested for the amount of CW that will be needed. I notice that some industries do their best to get a common volume for all over print applications. In some instances, this may apply, but if there is another application where a higher volume roller is needed, that application may be compromised or the lower volume applications are getting more coating applied than needed.

THE ECONOMICAL FACTORS

Control the exact amount needed with a +/- tolerance factor so you can save on cost. For example, if a particular press or application uses $1,000,000 a year on a specific coating and is applying 10% more than needed, there is an opportunity to cut back 10% and save $100,000 just by lowering the anilox volume by 10%. For instance, a 6bcm application that gets reduced to a 5.4 will yield a 10% savings. Look at the outcome of your print process and see if there is room to trim anilox volume and still meet product specifications. This is a common situation when putting down opaque whites. The consumption of that ink adds up fast. That is why the measuring phase of qualifying an ink or coating has to be done correctly for all products. This ensures the product resistance, as well as the consumption factor, is being evaluated efficiently. A banded anilox roller is a perfect way to optimize your CW. If you are in an industry that runs a variety of different coating types, save these banded rollers for future applications that may come in at a later date. Building a library of banded rollers will be a benefit to you over time at a comparative minimal cost.

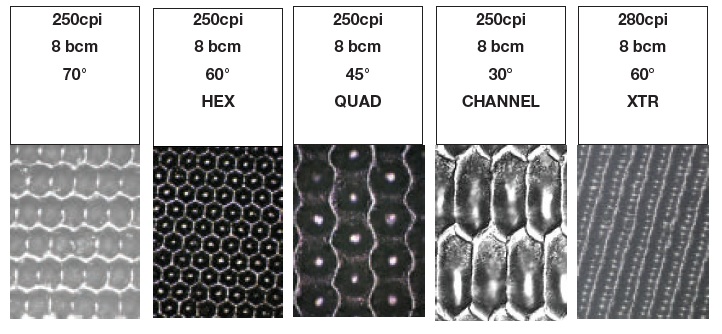

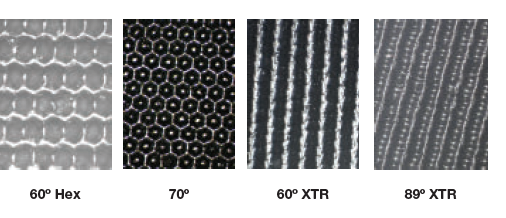

Trying a variety of geometries is another way to optimize the laydown of the coating, as well as the CW. The example below was a test run from a past application where the customer had issues with how the coating was laying down on the substrate. In the instance below, the far band, XTR 60° was the band chosen after the testing was done. It yielded the smoothness surface and gloss as well as CW.

ANILOX SPECIFICATIONS

How to approach specifying the anilox roller:

To select the proper line screen, volume and geometry for the coating, all factors have to be considered.

This can be done many ways. This is how I approach all my recommendations:

• Know the substrate, application and how the end user will receive the product.

• Make sure you have the coating worksheet from the coating supplier – % of solids is one of the specifications you will need to know about the coating.

• Find out what the target coat weight will be.

• Determine the engraved volume based on the target CW.

• Then determine which geometry will release best based on the coating chemistry and the cosmetic value of the coated surface. Is the surface visible, is it an over print coating, etc.?

The geometry will control how the coating is delivered to the substrate. Choose a geometry that will allow the coating to cycle through the cells and also release well. These two factors work together. Saturation levels of the coating will change depending on the substrate surface. Coated vs. uncoated materials will control amount of volume needed. The geometry as well may come into play when running a coated material or film compared to an uncoated paper or substrate.

GRAVURE APPLICATIONS

Lower depth-to-opening ratios should be considered when making recommendations for direct and variable speed gravure applications. Direct contact to the substrate is more efficient when using lower linescreens than what is used in a typical flexo application. These gravure applications have to be looked at differently. The final polish of the ceramic surface comes into play since there is direct contact to the substrate, and if this is a variable speed application, surface polish will affect how the anilox could pull the web or wear the rubber assist roller.

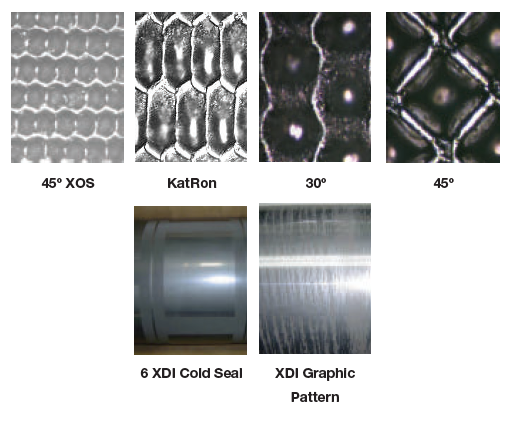

Once all these factors above are known, the whole package can be put together. Line screen, volume and geometry. Closed cell or channeled engravings are the choices. In many cases, channeled geometries work well with large particle coatings. These coatings are typically comprised of a carrier vehicle, such as a clear extender or a gloss varnish, and then particle is added. If line screen is not large enough you will not transfer enough of the particle component and the blade shear will just chop the coating into a slurry over a short period of time, creating a sludge in the coating pan or enclosed chamber.

COATING TYPES

STANDARD COATINGS:

All coatings that have very small particle composition will probably deliver well using the typical 60º hex geometry. As long as the surface texture is laid down smoothly, the 60º geometry will probably be acceptable. This geometry is the flexo standard in most applications for inks and coatings.

SILICONES:

Some coating types work on very low volumes like silicones do in some cases. This is where it is important to stay as low in line screen as possible, considering the volume may be as low as 2bcm, cell openings will be smaller than usual.

TACTILE/TEXTURED COATINGS:

Coatings that are composed of smaller to larger particles have to be approached differently. I typically start with the 60º geometry and if that does not apply, I go to my alternatives. What forces me to go away from the 60º geometry is tacky-to-high viscosity coatings. Any closed cell will have issues trying to deposit a viscous coating, especially adhesives.

ADHESIVES:

If your existing applications are running inefficiently (issues like foaming, inconsistent weight) you may need to consider changing the geometry. Inefficient delivery of coatings is due to the lack of recycling of the coating out of the cells. Inefficient can be defined where the coating will start out running fine and over a matter of a few hours it will drop off in coat weight or cells will completely plug up. This is due to a lack of recycling the coating through the cells. Adhesives tend to run better with channeled or opened cell types. Water and solvent adhesives will tend to plug faster if they do not cycle through the cell efficiently. Inks or coatings that are formulated for drying on films will also respond that way. UV adhesives tend to deliver more efficiently since they do not cure until they reach the lamps, but the geometry selected can still assist in the smoothness of the final surface laydown of the coating. Even though these coating tend to run cleaner, changing geometry can still improveon their surface laydown.

MATTE, GLITTERS, ENCAPSULATED FRAGRANCES AND PARTICLE RELATED COATINGS:

With these types of coatings, line screen is an important factor. If the particle does not fit efficiently into the line screen, that component will not transfer. As already mentioned, these particles can break down with blade shear, which will turn the coatings into a slurry. At this point that may change the effectiveness of the coating. Using Matte Varnish as the example,when the coating breaks down into the slurry the matte finish may degrade. The geometries displayed here should accommodate these concerns. There are many other types of coatings that can be categorized with the ones mentioned above.

Take into consideration the particle being transferred. That is the component that you have to transfer to the substrate. The typical vehicle used to carry that coating is not the problematic component, the additive which can be glitter, mica, sand or other types of textured materials are the components that make the coating work. Increasing volume will not always improve the coating products’ effectiveness, it may, however, lay out too much vehicle, which may create curl in the substrate or blocking in roller or stacks.

ARE MY EXISTING APPLICATIONS OPTIMIZED?

To optimize your coating applications, ask yourself:

• Am I losing coat weight over short periods of time?

• In an ink application, am I seeing slight drop-offs in color over short periods of time?

• Am I forced to clean anilox rollers to regain coat weight?

• When looking into the cells with the handheld scope or the lab scope, is there dried ink or coating building up around cell walls?

• Are my blades wearing out too quickly? Not always a geometry issue but channeled cells tend to wear blades more than 60º hex cells do.

1. Lower your Line Screen. This increases the cell depth to the opening. Increasing the cell opening allows the coating to release more efficiently and also creates a shallower cell. It can change the way the ink per coating lays down, as well. Consider all factors when

making these changes.

2. Change the Geometry. Going from the closed cell structure to an open cell or channel allows the coating to release more efficiently. Making an adjustment in geometry could yield as high as 15% - 20% more coating, which allows for the cell to cycle out the coating more often, which will allow for a cleaner cell over time. Look over the geometries listed above to give you a few alternatives you can use.

XDI Options: XDI stands for Extreme Digital Imaging. This is where we can take a graphic file and engrave an image into the ceramic. These are custom cells that can be designed if needed.These are considered XDI. If a graphic file is supplied, we can fabricate most cell patterns based on a graphic design. These special patterns need to be tested to see if they are efficient compared to the standard offerings we have.

3. Banded roll testing. As shown, going in this direction is allowing the geometry in the different bands to show you how they will run. This is the best way to get a sideby-side example of your existing line screen and volume, as well as other types you want to test. Set up a banded roll test with the help of a coating expert if needed. They will help set the volume and geometry parameters for the desired application and improved deposit efficiency. These test parameters will give the best results so you can benchmark off the final results for volume adjustment if needed. Keep this banded roller for future testing of newer coatings over time.

Look around: Ask around within the industry. If you are experiencing these problems, most likely others are as well or they have already tried alternative solutions to improve the issues you are having.These are a few reasons why you may want to consider making changes to the coating application. Changing the geometry, which controls the delivery of

the coating and cleanliness of the cells, just may be what you need to finally fine tune the application. This should minimize the material waste, downtime and other expenses you’ve been living with.

Bill Poulson is Senior Technical Representative at global anilox supplier

Harper Corporation Of America.